Katherm HK E

Registration Code: 0VRWZT

Quality phase

ENV1.2 Version 2023 Risiken für die lokale Umwelt

QS 4

Metalle

Product description

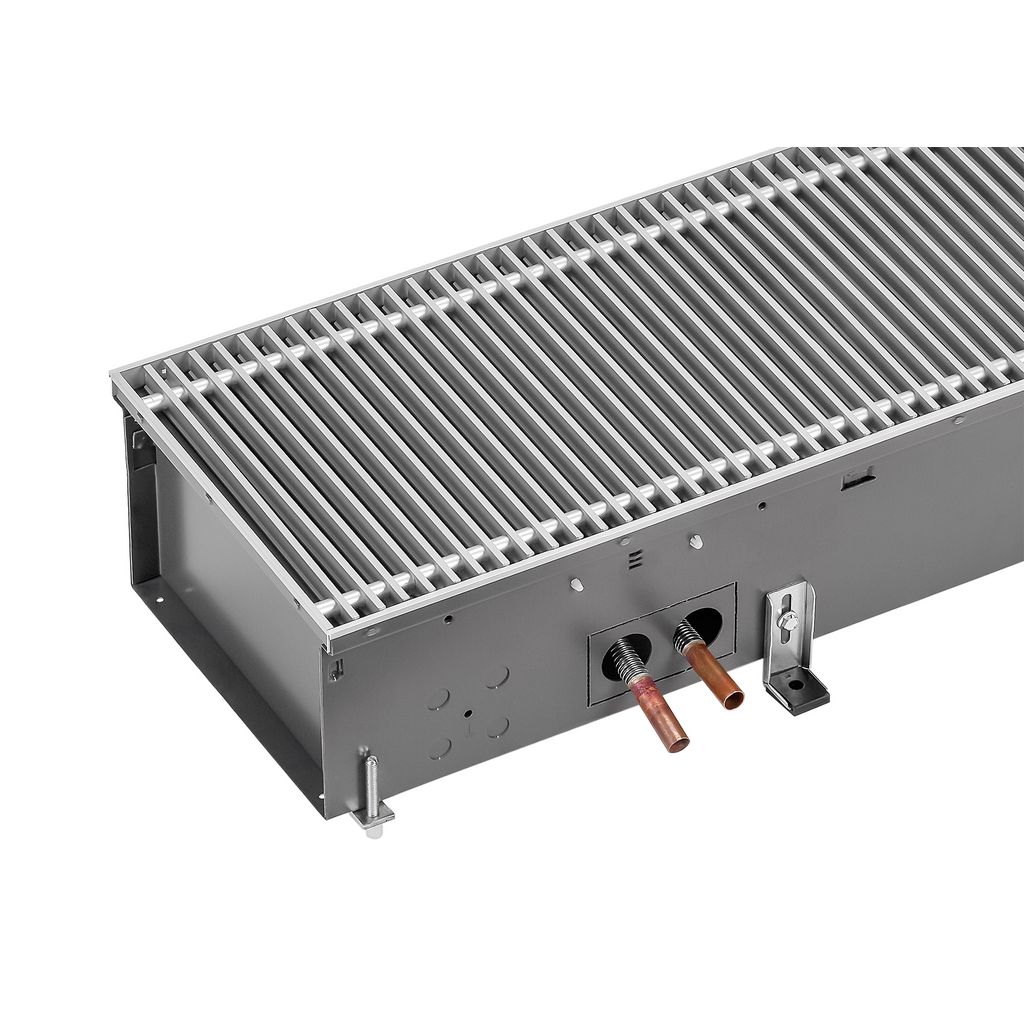

Trench units are installed along floor-to-ceiling window surfaces in the floor. The Katherm HK E provides a demand-oriented supply of filtered, heated or cooled circulating air into the room. The unit is available in various duct widths, heights and lengths for heating and cooling as required.The Katherm HK E has a convector through which hot water flows for heating and cold water flows for cooling. The convector consists of round copper pipes with aluminium fins. The units are designed as 2-pipe units and offer an additional directly selectable electric heating function with an integrated electric heating element. The use of the Katherm HK E means that there is less frequently a need for a switch-over between heating and cooling in transitional heating phases compared to a purely water-based 4-pipe system. This saves energy and enables the user to flexibly create their ideal climate. The EC cross-flow fan installed in the Katherm HK E ensures that air flows evenly through the convector. The fan is controlled by a stepless speed control via an external 0-10 V signal. In order to safely discharge the condensate produced, the units are equipped with a condensate tray and, if necessary, a condensate pump. The units are also equipped with an electrotechnical control system in order to be able to regulate the units according to the customer’s requirements.

The unit components are mounted in a floor trench, which is covered by a roll-up grille or a linear grille. This decorative cover of the trench unit is available in aluminium, brass and stainless steel. The Katherm HK E trench unit is used for the heating and cooling of rooms with large window areas. Exemplary areas of application for the unit are hotels, offices, sales and exhibition rooms.

Instructions for use

The units are used for heating and/or cooling all areas of buildings that need to be heated in winter and cooled in summer due to the high incidence of sunlight through the glass façades. Within the room, the unit needs to be connected to the building's heating/cooling/ventilation system and to the building's waste water and power network. The operating limits and limits of use must be observed.Reference to the DGNB system

ENV1.1 Building life cycle assessment

ENV1.1 Building life cycle assessment

Photochemical ozone creation potential (POCP)

1) Production stage

3,88E-01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

9,14E-03

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

1,03E-03

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-2,64E-01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Unit

kg NMVOC-Equivalent

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Total use of non-renewable primary energy (PENRT)

1) Production stage

1,00E+03 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

1,50E+01 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

1,63E+00 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-6,19E+02 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Total use of renewable primary energy (PERT)

1) Production stage

3,11E+02 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

3,29E+00 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

5,87E-02 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-1,56E+02 MJ

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

General life cycle assessment data

Building material class

not relevant

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Reference Unit

1 kW

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

If necessary, conversion of the reference unit

No conversion necessary

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

End of life cycle

76% of metal parts are recycled with the remaining 24% going to landfill, while 100% of plastic parts are incinerated for heat recovery.

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Useful life

20 years

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Global Warming Potential (GWP)

1) Production stage

7,46E+01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

1,04E+00

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

2,67E+00

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-4,78E+01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Unit

kg CO2-Equivalent

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Eutrophication (EP)

1) Production stage

8,15E-02

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

3,17E-03

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

2,61E-05

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-5,52E-02

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Unit

kg P-Eq. [EP-freshwater]; kg N-Eq. [EP-marine]; mol N-Eq. [EP-terrestrial]

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Acidification potential (AP)

1) Production stage

9,35E-01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

3,91E-02

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

8,32E-04

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-6,57E-01

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Unit

mol H+- Equivalent

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Ozone Depletion Potential (ODP)

1) Production stage

1,74E-06

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

2) Use stage

1,73E-08

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

3) End of life stage

1,23E-08

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

4) Benefits and loads beyond the system boundries

-1,25E-06

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

Unit

kg CFC11-Equivalent

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

ENV2.2 Potable water demand and waste water volume

ENV2.2 Potable water demand and waste water volume

Installation-specific connected load

Flow rate (for sanitary fittings)

not relevant l/sec

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Average flushing volume (of the sanitary equipment)

not relevant l/flush

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

ECO1.1 Life cycle costs

ECO1.1 Life cycle costs

Actual useful life

20 years

- Source

- EPD S-P-12154

- Quality

- [Externally audited specific manufacturer information]

PRO1.4 Ensuring sustainability aspects in tendering and contracting

PRO1.4 Ensuring sustainability aspects in tendering and contracting

Tender textes

Product-related tender texts available, reference to EPD and registration in the DGNB Navigator in the tender texts.

- Source

- Tender texts Katherm HK E

- Quality

- [Unaudited manufacturer specification]

PRO2.5 Preparation of sustainable use

PRO2.5 Preparation of sustainable use

Maintenance, inspection, operating and care instructions

Yes, included in assembly instructions.

- Source

- Assembly instructions Katherm HK E

- Quality

- [Unaudited manufacturer specification]

SOC1.2 Indoor air quality

SOC1.2 Indoor air quality

Indoor hygiene - volatile organic compounds VOCs

Formaldehyde concentration

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Other emission tests / labels

not relevant

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

TVOC value

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Approval test according to AgBB scheme is available

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

SOC1.3 Acoustic comfort

SOC1.3 Acoustic comfort

Rated building sound insulation value R`w

not relevant dB

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

SOC1.4 Visual comfort

SOC1.4 Visual comfort

Visual contact with the outside

Class of the sun/glare protection with regard to visual contact to the outside

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Colour rendering

Color rendering index Ra of artificial lighting

not relevant

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

TEC1.3 Quality of the building envelope

TEC1.3 Quality of the building envelope

Class of air permeability (joint permeability)

not relevant

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Heat transfer coefficient U

not relevant W/(m²K)

- Source

- Manufacturer

- Quality

- [Unaudited manufacturer specification]

Manufacturer note

Note on LCA data

The LCA data given were calculated according to the specifications of the EN 15804:2012+A2:2019 standard.Note on document download

All documents mentioned in this product profile (technical catalogue, environmental product declaration (EPD), assembly instructions) are available in their current version in the document download on the Kampmann GmbH & Co. KG website.Contact the manufacturer

Kampmann GmbH & Co. KG

Kampmann GmbH & Co. KG

Friedrich-Ebert-Straße 128-130 49811 Lingen (Ems)

Related products from this manufacturer

#72JX5X

Katherm QE 1700 mm

Kampmann GmbH & Co. KG

Bodenkanalheizungen Katherm QE sind die ideale Lösung, wenn der Einsatz eines Konvektors mit Pumpenwarmwasser nicht möglich oder nicht vorgesehen ist. Sie zeichnen sich durch energiesparende und sehr leise laufende EC-Querstromventilatoren in…

#EZ9W3J

Venkon XL - Baugröße 2

Kampmann GmbH & Co. KG

In Komfortgebäuden aller Art mit hohem Heiz- und Kühlbedarf sowie hohem Raumnutzer-Anspruch kommen Fan Coils zum Einsatz. Der Fan Coil Venkon XL ist in vier Baugrößen für jede Anwendung und jedes zu kühlende und/oder zu beheizende Gebäude erhältlich.…

#4KPU6Y

KaDeck einseitig ausblasend, trockene Kühlung

Kampmann GmbH & Co. KG

In Büroräumen mit hohem Glasflächenanteil und Personenaufkommen entstehen Kühllasten, die ohne eine Klimaanlage nicht abgeführt werden können. Für diesen Einsatzbereich bietet der KaDeck eine flexible Raumklimatisierung für die Decke zum Kühlen und…